Aluminum billet sanannen zaɓi ne ga masana'antu daban-daban yayin da suke taka muhimmiyar rawa a fagage daban-daban kamar na kera motoci, sararin samaniya da gine-gine saboda nauyinsu mai sauƙi, ƙarfinsu mai ƙarfi da kyakkyawan yanayin zafi.Koyaya, tsarin simintin billet na aluminum yana buƙatar kayan aiki na musamman da kayan don tabbatar da samfur mai inganci.Wani muhimmin sashi shine mai rarrabawa.

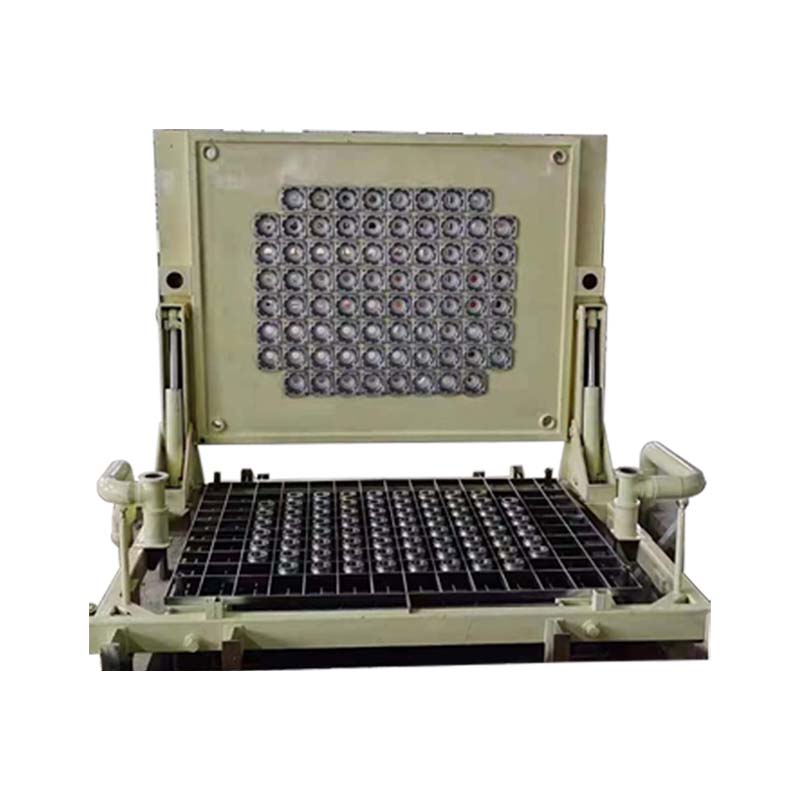

Therarraba wankiwani bangare ne na tsarin simintin simintin billet na aluminium, ana amfani da shi don yin farantin karfe kuma an tsara shi donzafi saman simintin gyaran kafana aluminum da aluminum gami.Ruwan aluminum yana fitowa daga cikintanderukuma ya wuce ta ayumbu wanki sannan ta hanyar aakwatin tacega mai rarrabawa.Yana da alhakin ƙwanƙwasa da ingantaccen kwararar narkakkar aluminum a cikin ƙirar, yana tabbatar da daidaito da amincin samfurin ƙarshe.

Don saduwa da buƙatun buƙatun buƙatun tsarin simintin billet na aluminum, ana amfani da wanki mai rarrabawa da fiber na silicate na aluminum da yumbu.Wannan haɗin gwiwar yana ba da kyakkyawan rufin zafi, yana tabbatar da ƙarancin zafi yayin aikin simintin.Kyakkyawan rufin thermal kuma yana taimakawa wajen kiyaye zafin jiki akai-akai a cikin mold, wanda ke haɓaka ingancin simintin kuma yana rage lahani.Bugu da ƙari, mai rarraba mai rarraba yana da kyakkyawan juriya na zafi, yana ba su damar yin tsayayya da yanayin zafi na ruwa na aluminum.Wannan babban juriya na zafin jiki yana tabbatar da dorewa da tsawon rayuwar mai rarrabawa, yana mai da shi zaɓi mai tsada don masu sana'a na simintin gyare-gyare.

Wani muhimmin fasali na rarraba wanki shine kayan aikin su na aluminum.Narkar da Aluminum yana ƙoƙarin mannewa saman kayan, wanda ke haifar da samuwar slag da raguwar inganci.Halin da ba shi da kullun na launder na rarrabawa zai iya hana haɓakar slag, yana tabbatar da ingantaccen ruwa na aluminum yayin aikin simintin gyare-gyare da kuma ƙara yawan tanadin lokaci.Distribution launder shima yana da ƙarfi kuma yana da juriya ga zazzagewa kuma yana iya jure kwararar aluminum ba tare da lalacewa ko lalacewa ba.Wannan babban ƙarfin ba kawai yana tabbatar da amincin samfurin simintin gyaran kafa ba, har ma yana adana farashin masana'anta ta hanyar rage buƙatar sauyawa akai-akai.

Baya ga kyawawan kaddarorin kayan, wankin rarrabawa yana ba da juriya mai inganci.Halin lalacewa na narkar da aluminum na iya lalata aikin kayan aiki, yana rage ingancin samfurin ƙarshe.Koyaya, juriya na lalatawar wanki yana tabbatar da tsabta da amincin ruwan aluminium a duk lokacin aikin simintin.

Bugu da kari, rarraba launder gabaɗaya suna samuwa a cikin masu girma dabam daga 3 ″ zuwa 9 ″, 10″, 12″, 14″, 16″, 18″, 20″, amma masana'antun na iya siffanta girman girman wanki don tabbatar da dacewa da kowane. aikace-aikacen simintin gyare-gyare.Wannan sassauci yana ba abokan ciniki damar saduwa da buƙatun samarwa daban-daban da haɓaka yawan aiki.

Don tabbatar da ingancin kayan wanki, zhelu yana amfani da dabarun masana'antu na ci gaba kamar simintin ruwa.Wannan mafi kyawun tabbatar da aikin samfur kuma yana inganta ingancin samfurin ƙarshe.Haɗuwa da hanyoyin masana'antu na ci gaba da kayan aiki masu inganci suna sa rarraba launder ya zama wani ɓangare na tsarin simintin aluminum.

A taƙaice, yin amfani da wanki mai rarrabawa a cikin simintin gyare-gyare na aluminum yana da mahimmanci don tabbatar da samar da ingantaccen billet na aluminum.Kyakkyawan rufin zafi mai zafi, juriya na zafin jiki, kaddarorin aluminium mara ƙarfi, ƙarfi mai ƙarfi, rayuwa mai tsayi, juriya ga ƙwanƙwasa da lalata ruwa na aluminium ya sa ya zama kyakkyawan zaɓi ga masana'antun masana'anta.Har ila yau, mai rarraba rarraba yana amfana daga ikonsa na musamman don ƙayyadaddun buƙatu, yana mai da shi mafita mai mahimmanci da tsada.Tare da fasahar masana'antu na ci gaba da kayan kayan aiki masu mahimmanci, masu rarraba wanki sun zama wani ɓangare na tsarin simintin billet na aluminum, ingantaccen tuki da ingancin samfur a cikin masana'antar aluminum.

Lokacin aikawa: Satumba-09-2023