I. gajarta

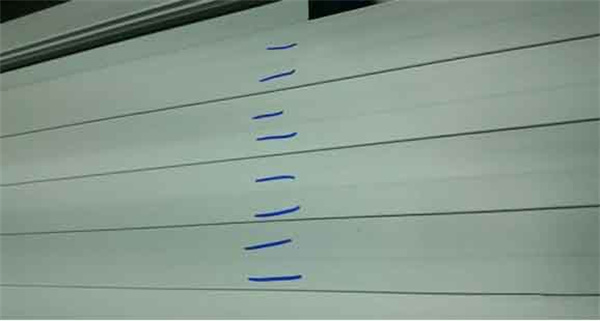

A ƙarshen wutsiya na wasu samfuran da aka fitar, bayan ƙananan haɓakawa, akwai wani abu mai kama da ƙaho a tsakiyar sashin giciye, wanda ake kira wutsiya mai raguwa.

Gabaɗaya, wutsiya na samfur na gaba ya fi tsayi fiye da na baya extrusion, kuma gami mai laushi ya fi tsayi da ƙarfi.Rushewar samfurin da aka fitar na gaba yawanci yana cikin nau'i na nau'i mai rarrafe na annular, kuma raguwar samfurin da aka fitar ya fi yawa a cikin siffar mazurari ta tsakiya.

The karfe ne extruded zuwa baya karshen, da ingot fata da kuma kasashen waje inclusions tara a kan matattu kusurwa na extrusion Silinda ko gasket kwarara a cikin samfurin don samar da wani sakandare shrinkage;lokacin da ragowar kayan ya yi tsayi da yawa kuma tsakiyar samfurin ba a wadatar da shi ba, nau'in raguwa ne.Daga ƙarshen wutsiya zuwa gaba, wutsiya a hankali ya zama mai sauƙi kuma ya ɓace gaba ɗaya.

Babban dalilin raguwa

1. Abubuwan da suka rage sun kasance gajere ko tsayin ƙarshen yanke samfurin bai dace da ka'idoji ba;

2. Kushin extrusion ba shi da tsabta kuma yana da tabo mai;

3. A cikin mataki na gaba na extrusion, saurin extrusion yana da sauri sosai ko kuma ba zato ba tsammani;

4. Yi amfani da gurɓataccen kushin matsi (wani kushin da aka ɗaga a tsakiya);

5. Yanayin zafin jiki na silinda extrusion ya yi yawa;

6. Silinda extrusion da ma'auni na extrusion ba a daidaita su ba;

7. Fuskar ingot ba ta da tsabta, akwai tabo mai, ciwace-ciwacen daji da nadewa da sauran lahani ba a cire;

8. Hannun ciki na silinda extrusion ba shi da tsabta ko maras kyau, kuma ba a tsaftace rufin ciki tare da kushin tsaftacewa a cikin lokaci.

Hanyar rigakafi

1. Bar ragowar kuma yanke wutsiyoyi kamar yadda ake bukata;

2. Tsabtace tsaftar tsafta;

3. Inganta ingancin farfajiya na ingot;

4. Da kyau kula da extrusion zafin jiki da kuma gudun don tabbatar da m extrusion;

5. Sai dai yanayi na musamman, an haramta shi sosai don shafa man fetur a saman kayan aiki da mold;

6. Gasket an sanyaya sosai.

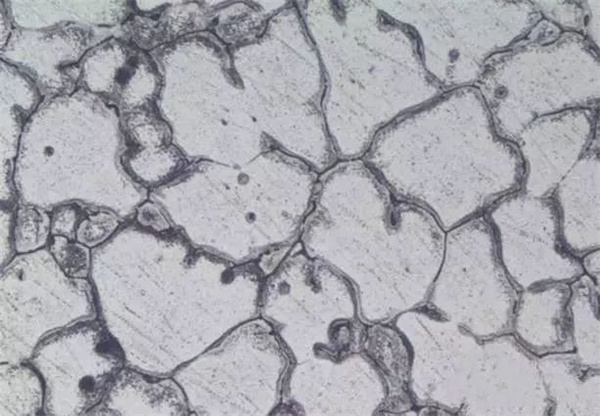

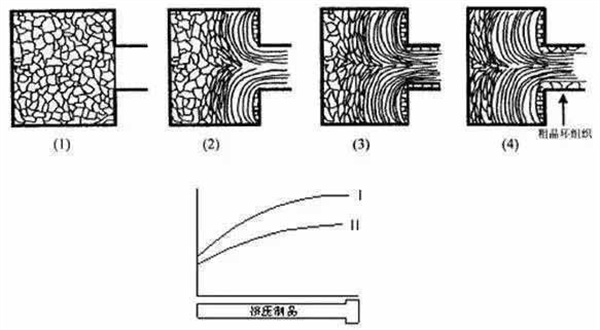

II.M zoben crystal

Wasu samfuran aluminium da aka fitar da su suna samar da wani yanki mai tsattsauran ra'ayi da aka yi recrystallized tare da gefen samfurin akan ƙaramin gwajin haɓakawa bayan maganin maganin, wanda ake kira zoben hatsi.Saboda nau'i-nau'i daban-daban da hanyoyin sarrafawa na samfurori, ana iya samar da nau'i-nau'i-nau'i, nau'i-nau'i-nau'i da sauran nau'i-nau'i na nau'i-nau'i.Zurfin zobe mai laushi a hankali yana raguwa daga wutsiya zuwa gaba kuma ya ɓace gaba ɗaya.Hanyar samar da farko ita ce yankin ƙwayar hatsi da aka kafa a saman samfurin bayan zafi mai zafi, kuma an kafa yankin hatsi mai mahimmanci bayan dumama da magani.

Babban dalilin m crystal zobe

1. Nakasar extrusion mara daidaituwa

2. Yanayin zafin zafin jiki yana da yawa kuma lokacin riƙewa ya yi tsayi sosai, don haka hatsi ya girma;

3. Abubuwan sinadaran na zinariya ba su da ma'ana;

4. Ƙaƙƙarfan ƙarfin ƙarfafawa na gaba ɗaya yana da ƙananan zobba bayan maganin zafi, musamman ma siffofi da sanduna na 6a02, 2a50 da sauran kayan haɗi sune mafi tsanani, wanda ba za a iya kawar da shi ba kuma za'a iya sarrafawa kawai a cikin wani yanki;

5. Ƙarƙashin ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙanƙara ko nakasar ba ta isa ba, ko kuma a cikin kewayon nakasawa mai mahimmanci, kuma yana da sauƙi don samar da zobe na crystal.

Hanyar rigakafi

1. bangon ciki na silinda extrusion yana da santsi kuma mai tsabta, yana samar da cikakken hannun riga na aluminum don rage raguwa a lokacin extrusion;

2. Nakasar ya kamata ya zama cikakke da daidaituwa kamar yadda zai yiwu, kuma sigogin tsari kamar zafin jiki da sauri ya kamata a sarrafa su da kyau;

3. Guji zafin maganin maganin zafin jiki ya yi yawa ko lokacin riƙewa ya yi tsayi;

4. Extrusion tare da porous mutu;

5. Extrusion ta hanyar baya extrusion da kuma a tsaye extrusion hanya;

6. Samar da ta hanyar maganin magani-zane-tsufa hanya;

7. Daidaita jimlar abun da ke ciki na zinari kuma ƙara haɓakar abubuwan hana recrystallization;

8. Yi amfani da extrusion zafin jiki mafi girma;

9. Wasu gami ingots ba su homogenized, da kuma m hatsi zobe ne m a lokacin extrusion.

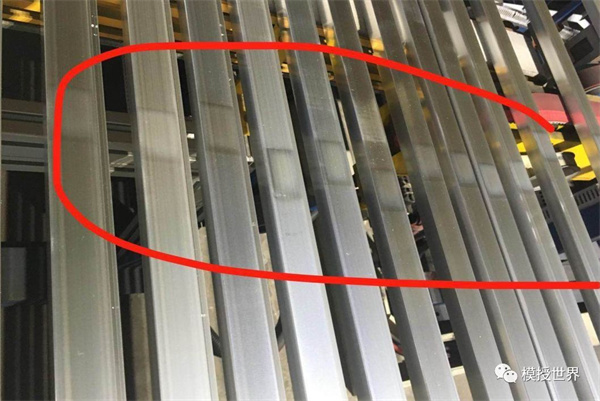

III, yawo

Wannan lahani ne na lalata fata da aka samu lokacin da kwararan ƙarfe ya yi daidai da kamanni, kuma saman ingot ɗin yana gudana cikin samfurin tare da mu'amala tsakanin ƙirar da yankin na roba na gaba.A kan juzu'in gwajin ƙaramar ƙararrawa, ya bayyana cewa akwai lahani na yadudduka daban-daban a ƙarshen ɓangaren giciye.

Babban dalilin stratification

1. Akwai kura a saman ingot ko ingot yana da manyan rarrabuwar kawuna maimakon fatar mota, ciwace-ciwacen karfe da sauransu, wadanda suke da saukin yi;

2. Akwai buras a saman babur ko datti kamar tabon mai, sawdust, da sauransu, wadanda ba a tsaftace su kafin fitar da su;

3. Matsayin ramin mutuwa ba shi da ma'ana, kusa da gefen silinda extrusion;

4. Ana amfani da kayan aiki mai mahimmanci ko kuma akwai datti a cikin bushing na silinda extrusion, wanda ba za a iya tsaftacewa da maye gurbinsa a lokaci ba;

5. Bambancin diamita na kushin extrusion ya yi yawa;

6. Zazzabi na silinda extrusion ya fi girma fiye da na ingot.

Hanyar rigakafi

1. Mahimman ƙira na ƙira, dubawa na lokaci da maye gurbin kayan aikin da ba su dace ba;

2. Ba a shigar da ingots marasa cancanta a cikin tanderun;

3. Bayan yanke ragowar kayan, ya kamata a tsaftace shi ba tare da tsayawa ga man shafawa ba;

4. Ci gaba da rufin silinda extrusion, ko tsaftace rufin cikin lokaci tare da gasket.

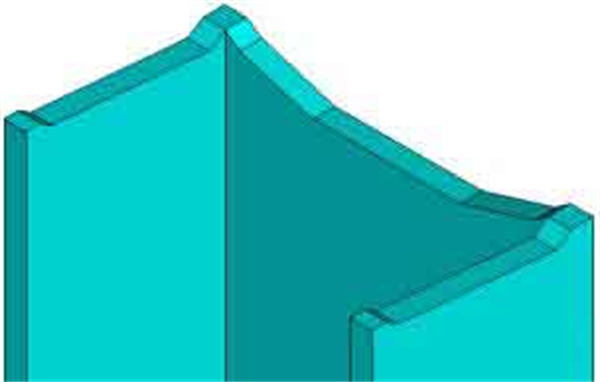

IV.Mara kyau waldi

Al'amarin na weld delamination ko rashin kammala walda na m samfurin extruded da tsaga mutu a walda ake kira matalauta waldi.

Babban dalilin rashin walda

1. Rashin daidaituwa yana da ƙanana, zazzabi mai gudana yana da ƙasa, kuma saurin tasirin sauri yana da sauri;

2. Extrusion ulu ko kayan aiki ba su da tsabta;

3. Mai da m;

4. Tsarin ƙira mara kyau, rashin isasshen ko rashin daidaituwa na matsa lamba na hydrostatic, ƙira mara kyau na ramukan shunt;

5. Akwai tabon mai a saman ingot.

Hanyar rigakafi

1. Daidaita haɓaka haɓakar haɓakar extrusion, zafin zafin jiki da saurin extrusion;

2. Ma'ana mai ma'ana da ƙira na ƙira;

3. Ba a mai da gas ɗin extrusion da gasket kuma ana kiyaye su da tsabta;

4. Yi amfani da ingots tare da shimfidar wuri mai tsabta.

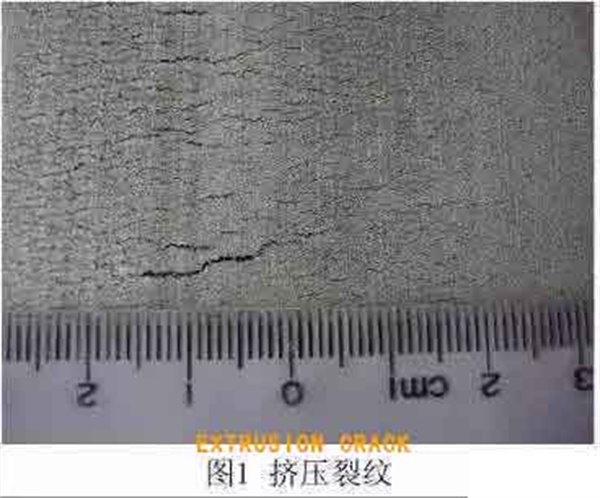

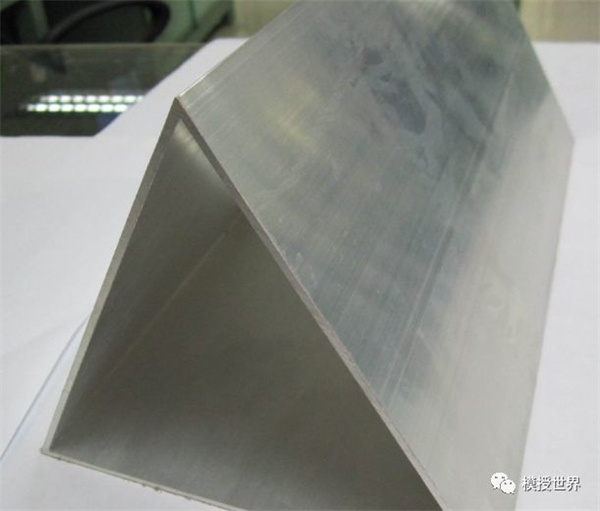

V. Fashewar ƙura

Wannan wani ɗan ƙarami ne mai siffar baka a gefen ɓangaren gwajin da aka cire na samfurin, da fashe lokaci-lokaci a wani kusurwa tare da madaidaiciyar alkiblarsa, wanda ke ɓoye a ƙarƙashin epidermis a cikin lokuta masu haske, da kuma ɓarna a saman Layer na waje. a lokuta masu tsanani, wanda zai lalata ci gaba da karfe.Ana samun tsagewar tsagewar lokacin da saman ƙarfe ya tsage ta hanyar wuce gona da iri na juzu'i na katangar mutu yayin aikin extrusion.

Babban dalilin extrusion fasa

1. Gudun extrusion yana da sauri sosai;

2. Extrusion zafin jiki ya yi yawa;

3. Gudun extrusion yana jujjuyawa da yawa;

4. Zazzabi na ulun extruded ya yi yawa;

5. Lokacin da aka fitar da ƙwayar cuta, tsarin mutuwar ya kasance kusa da cibiyar, don haka ma'aunin ƙarfe na tsakiya bai isa ba, don haka bambanci tsakanin tsakiya da iyakar iyakar ya yi girma;

6. The ingot homogenization annealing ba shi da kyau.

Hanyar rigakafi

1. Tsantsar aiwatar da ƙayyadaddun bayanai na dumama da extrusion daban-daban;

2. Binciken akai-akai na kayan aiki da kayan aiki don tabbatar da aiki na yau da kullum;

3. Gyara ƙirar ƙira kuma a hankali aiwatar da shi, musamman ƙirar ƙirar ƙirar gada, ɗakin walda da radius gefen, da dai sauransu ya zama m;

4. Rage yawan abun ciki na sodium a cikin manyan ma'adinan aluminum aluminum;

5. Ingot ɗin yana kama da juna kuma ana goge shi don inganta filastik da daidaito.

VI.Kumfa

Ƙarfen fata na gida yana ci gaba da rabuwa ko kuma ya daina rabuwa da ƙarfen tushe, kuma yana bayyana a matsayin madauwari guda ɗaya ko mai siffar tsiri wanda aka ɗaga aibi, wanda ake kira kumfa.

Babban dalilin kumfa

1. Lokacin extruding, silinda extrusion da extrusion pad suna da datti kamar danshi da mai;

2. Saboda lalacewa na silinda extrusion, iska tsakanin sashin da aka sawa da ingot ya shiga cikin karfe a lokacin extrusion;

3. Akwai danshi a cikin mai;

4. Tsarin ingot kanta yana da lahani da lahani;

5. Yanayin zafin zafin jiki yana da yawa, lokacin riƙewa ya yi tsayi sosai, kuma yanayin zafi a cikin tanderun yana da girma;

6. Abubuwan da ke cikin hydrogen a cikin samfurin ya yi yawa;

7. Extrusion Silinda zafin jiki da ingot zafin jiki sun yi yawa.

Hanyar rigakafi

1. Ya kamata a kiyaye saman kayan aiki da ingots mai tsabta, santsi da bushe;

2. Da kyau zayyana girman ma'auni na silinda extrusion da gas ɗin extrusion, bincika girman kayan aiki akai-akai, gyara silinda extrusion a lokacin da akwai babban ciki, kuma gas ɗin extrusion bai kamata ya kasance cikin haƙuri ba;

3. Tabbatar cewa mai mai mai tsabta kuma ya bushe;

4. Tsaya bin tsarin aiki na extrusion, shayewa a cikin lokaci, yanke daidai, kada ku yi amfani da man fetur, cire kayan da aka rage gaba daya, kiyaye blanks da gyare-gyare masu tsabta kuma ba gurbata ba.

VII.Kwasfa

Wannan shine sabon abu na rabuwa na gida tsakanin karfen fata da karfen tushe na samfurin aluminium alloy extrusion.

Babban dalilin peeling

1. Lokacin da aka maye gurbin gami da fitar da gwangwani, bangon ciki na silinda extrusion yana manne da daji da aka kafa ta asalin ƙarfe, wanda ba a tsaftace shi da kyau;

2. Silinda extrusion da kushin extrusion ba su dace da kyau ba, kuma bangon ciki na silinda extrusion yana da layi tare da ragowar karfe na gida;

3. An extruded da lubricating extrusion Silinda;

4. Akwai ƙarfe akan ramin mutu ko kuma bel ɗin aiki na mutu ya yi tsayi da yawa.

Hanyar rigakafi

1. Tsaftace tsaftataccen silinda na extrusion lokacin extruding gami;

2. Hankali tsara girman ma'auni na silinda extrusion da gasket na extrusion, duba girman kayan aiki akai-akai, kuma gas ɗin extrusion ba zai iya zama daga haƙuri ba;

3. Tsaftace ragowar ƙarfe a kan ƙura a cikin lokaci.

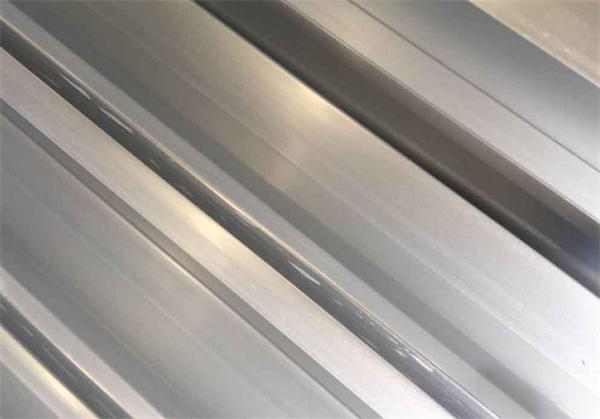

VIII.Scratches

Tabon inji guda ɗaya wanda ke haifar da tuntuɓar abubuwa masu kaifi da saman samfurin yayin zamewar dangi ana kiran su karce.

Babban dalilin karce

1. Rashin daidaituwa na kayan aiki, jagororin da ba su da kyau da kayan aiki, kusurwoyi masu kaifi ko abubuwa na waje, da dai sauransu;

2. Akwai kwakwalwan ƙarfe a kan bel ɗin aiki na mold ko bel ɗin aiki ya lalace;

3. Akwai yashi ko fashe-fashe na ƙarfe a cikin man mai;

4. Ayyukan da ba daidai ba a lokacin sufuri da kuma yada ba daidai ba.

Hanyar rigakafi

1. Bincika da goge bel ɗin aiki na mold a cikin lokaci;

2. Duba tashar fitar da samfurin, ya kamata ya zama santsi, kuma hanyar jagora za a iya lubricated da kyau;

3. Hana shafan injina da zazzagewa yayin sarrafawa.

IX.Kumburi

Tabo da aka samu a saman samfuran ko samfuran da suka yi karo da wasu abubuwa ana kiran su rauni.

Babban dalilin bumps

1. Tsarin aikin benci da kayan tarawa ba shi da ma'ana;

2. Rashin kariya na ƙarfe mara kyau na kwandunan kayan, kayan aiki, da dai sauransu;

3. Kar a rike shi da kulawa lokacin aiki.

Hanyar rigakafi

1. Aiki a hankali, rike da kulawa;

2. Niƙa daga kusurwoyi masu kaifi, kuma a rufe kwandon da tara tare da dunnage da kayan laushi.

X. Tsage

Tabo da aka rarraba a cikin daure a saman samfurin wanda ke haifar da zamewar dangi ko tarwatsewa bayan saman samfurin da aka fitar ya zo cikin hulɗa da gefuna ko saman wasu abubuwa ana kiransa scratches.

Babban dalilin karce

1. Ana sawa da ƙwayar cuta mai tsanani;

2. Saboda yawan zafin jiki na ingot, ramin mutu yana mannewa aluminium ko bel ɗin da ke aiki ya lalace;

3. Datti kamar graphite da mai sun fada cikin silinda extrusion;

4. Samfuran suna motsawa tare da juna, don haka an ɗora saman da kuma fitar da extrusion ba daidai ba ne, wanda ya sa samfurori ba su gudana a cikin layi madaidaiciya, wanda ya haifar da raguwa tsakanin kayan aiki da hanyar jagora da aikin aiki.

Hanyar rigakafi

1. Bincika da maye gurbin da ba su cancanta ba a cikin lokaci;

2. Sarrafa yawan zafin jiki na ulu;

3. Tabbatar cewa saman silinda extrusion da ulu mai tsabta da bushe;

4. Sarrafa saurin extrusion don tabbatar da saurin daidaituwa.

XI.Alamun ƙira

Wannan alama ce ta rashin daidaituwa na tsayin daka a saman samfurin da aka fitar, kuma duk samfuran da aka fitar suna da alamun mutuwa zuwa digiri daban-daban.

Babban dalilin mold alamomi

Babban dalili: bel ɗin aiki na mold ba zai iya cimma cikakkiyar santsi ba.

Hanyar rigakafi

1. Tabbatar cewa saman bel ɗin aiki mai tsabta yana da tsabta, santsi kuma ba tare da gefuna masu kaifi ba;

2. Maganin nitriding mai ma'ana don tabbatar da taurin saman;

3. Daidaita gyaran ƙira;

4. Ya kamata a tsara bel ɗin aiki da kyau, kuma bel ɗin aiki kada ya yi tsayi da yawa.

XII.Karkatar, lankwasa, kaɗa

Lamarin da ke karkatar da sashin giciye na samfurin da aka fitar da shi a kusurwar kusurwar kusurwa ana kiransa murɗawa.Al'amarin cewa samfurin yana lanƙwasa a madaidaiciyar hanya ko siffar wuƙa ba ta miƙe ba ana kiranta lanƙwasawa.Ci gaba da ci gaba da ci gaba da rashin daidaituwar al'amari wanda ke faruwa a cikin tsayin daka na samfurin ana kiransa taguwar ruwa.

Babban abubuwan da ke haifar da karkatarwa, lankwasa, da raƙuman ruwa

1. Tsarin tsari da tsari na ramukan mutu ba su da kyau, ko girman rarraba bel ɗin aiki bai dace ba;

2. Rashin daidaito machining na ramukan mutu;

3. Ba a shigar da jagorar da ta dace ba;

4. Gyaran gyare-gyare mara kyau;

5. Rashin zafin extrusion mara kyau da sauri;

6. Samfurin ba a daidaita shi ba kafin maganin maganin;

7. Rashin daidaituwa a lokacin jiyya na zafi na kan layi.

Hanyar rigakafi

1. Babban matakin ƙirar ƙira da masana'anta;

2. Shigar da jagora mai dacewa, jan hankali da extrusion;

3. Yi amfani da lubrication na gida, gyaran gyare-gyare da juyawa ko canza ƙirar ramin shunt don daidaita ƙimar ƙarfe;

4. Daidaitaccen daidaita zafin jiki na extrusion da sauri don sa nakasawa ya zama iri ɗaya;

5. Daidaita rage yawan zafin jiki na maganin maganin ko ƙara yawan zafin jiki na ruwa don maganin maganin;

6. Tabbatar da sanyaya uniform a lokacin quenching kan layi.

XIII.Lankwasawa mai wuya

Lankwasawa kwatsam na samfurin extruded wani wuri a cikin tsayin daka ana kiransa lanƙwasawa mai wuya.

Babban dalilin lankwasawa mai wuya

1. Gudun extrusion mara daidaituwa, canzawa kwatsam daga ƙananan gudu zuwa babban gudu, ko canzawa kwatsam daga babban gudu zuwa ƙananan gudu, da tsayawa kwatsam;

2. Ci gaba da motsa samfurin yayin aiwatar da extrusion;

3. The aiki surface na extruder ne m.

Hanyar rigakafi

1. Kada ka tsaya a bazuwar ko canza saurin extrusion ba zato ba tsammani;

2. Kada ku motsa bayanin martaba ba zato ba tsammani da hannu;

3. Tabbatar cewa tebur na fitarwa yana da lebur kuma teburin abin nadi na fitarwa yana da santsi, ba tare da al'amuran waje ba, kuma samfuran da aka haɗa ba su da matsala.

XIV.Hemp noodles

Wannan ita ce lahani na saman samfurin da aka fitar, wanda ke nufin cewa saman samfurin shine ci gaba da flakes, tabo, ramuka, wake na karfe, da dai sauransu tare da ƙananan rashin daidaituwa.

Babban dalilin pockmark

1. Taurin gyambo bai isa ba ko taurin bai yi daidai ba;

2. Extrusion zafin jiki ya yi yawa;

3. Gudun extrusion yana da sauri sosai;

4. Belin aiki na mold yana da tsayi da yawa, m ko makale da karfe;

5. Tushen da aka fitar ya yi tsayi da yawa.

Hanyar rigakafi

1. Inganta taurin da taurin uniformity na mold aiki bel;

2. Zazzage silinda extrusion da ingot bisa ga ka'idoji, kuma amfani da saurin extrusion da ya dace;

3. Haƙiƙa ƙira ƙirar ƙira, rage ƙarancin bel ɗin aiki, da ƙarfafa dubawar saman, gyarawa da gogewa;

4. Yi amfani da madaidaicin tsayin ingot.

XV.Karfe matsi

A lokacin aikin extrusion, ana danna guntun ƙarfe a saman samfurin, wanda ake kira danna ƙarfe.

Babban abubuwan da ke haifar da kutsen karfe:

1. Ƙarshen ulu ba daidai ba ne;

2. Wurin ciki na ulu yana makale da ƙarfe ko man mai ya ƙunshi tarkacen ƙarfe da sauran datti;

3. Ba a tsabtace silinda extrusion ba, kuma akwai wasu tarkacen ƙarfe;

4. An nutsar da ingot cikin wasu ƙarfe na baƙin ƙarfe;

5. Akwai slag hada da ulu.

Hanyar rigakafi

1. Cire burrs a kan ulu;

2. Tabbatar cewa saman ulu da man shafawa suna da tsabta kuma bushe;

3. Tsaftace tarkacen karfe a cikin mold da extrusion cylinder;

4. Zaɓi ulu mai inganci.

XVI.Ba karfen latsawa ba

Abubuwan waje kamar dutse baƙar fata suna danna cikin ciki da waje na samfurin extruded, wanda ake kira indentation mara ƙarfe.Bayan da aka kwashe abubuwan waje, samfurin na ciki na ciki zai nuna damuwa na nau'i daban-daban, wanda zai lalata ci gaba da samfurin.

Babban dalilin kutse ba karfe ba

1. The graphite barbashi size ne m ko agglomerated, dauke da danshi ko mai, da stirring ne m;

2. Wurin walƙiya na man silinda yana da ƙasa;

3. Matsakaicin man silinda da graphite bai dace ba, kuma akwai graphite da yawa.

Hanyar rigakafi

1. Yi amfani da ƙwararren graphite kuma kiyaye shi bushe;

2. Tace da amfani da ingantaccen man mai;

3. Sarrafa rabon lubricating mai da graphite.

XVII.Lalacewar saman

Abubuwan da aka fitar waɗanda ba a yi amfani da su ba, saman samfurin da aka fitar, bayan sinadarai ko electrochemical tare da matsakaicin waje, yana haifar da lahani da lalacewa ta gida na farfajiyar, wanda ake kira corrosion.Samfurin da aka lalatar yana rasa hasken ƙarfensa, kuma a lokuta masu tsanani, ana samar da samfuran lalata-fari mai launin toka a saman.

Babban sanadin lalatawar ƙasa

1. Samfurin yana nunawa ga kafofin watsa labaru masu lalata irin su ruwa, acid, alkali, gishiri, da dai sauransu yayin samarwa, ajiya da sufuri, ko kuma an ajiye shi a cikin yanayi mai laushi na dogon lokaci;

2. Matsakaicin abun da ke ciki mara kyau;

Hanyar rigakafi

1. Ka kiyaye samfurin samfurin da kuma samarwa da yanayin ajiya mai tsabta da bushe;

2. Sarrafa abun ciki na abubuwa a cikin gami.

XVIII.Bawon lemu

Fuskar samfurin da aka fitar yana da wrinkles mara daidaituwa kamar bawo orange, wanda kuma aka sani da wrinkles.Yana haifar da ƙananan hatsi yayin extrusion.Ƙarƙashin ƙwayar hatsi, mafi mahimmancin wrinkles.

Babban dalilin kwasfa orange

1. Tsarin ingot bai dace ba kuma maganin homogenization bai isa ba;

2. Yanayin extrusion ba su da ma'ana, kuma hatsi na kayan da aka gama suna da yawa;

3. Yawan mikewa da mikewa yayi yawa.

Hanyar rigakafi

1. Mahimmanci sarrafa tsarin homogenization;

2. Nakasar ya kamata ya zama daidai kamar yadda zai yiwu ( sarrafa zafin extrusion, saurin gudu, da sauransu).

3. Sarrafa adadin gyaran tashin hankali kada yayi girma sosai.

XIX.Rashin daidaituwa

Bayan extrusion, wurin da kaurin samfurin ke canzawa a kan jirgin yana bayyana maƙarƙashiya ko maɗaukaki.Gabaɗaya, ba za a iya kiyaye shi da ido tsirara ba.Bayan jiyya na saman, inuwa masu kyau ko inuwa na kashi suna bayyana.

Babban dalilin rashin daidaituwa

1. Ba a tsara bel ɗin da ke aiki yadda ya kamata ba, kuma gyaran gyare-gyare ba a cikin wuri ba;

2. Girman rami na shunt ko pre-chamber bai dace ba, kuma ƙarfin jawowa ko fadada bayanin martaba a cikin giciye yana haifar da ɗan canji a cikin jirgin sama;

3. Tsarin sanyaya ba daidai ba ne, kuma saurin sanyi na ɓangaren bango mai kauri ko ɓangaren da ke haɗuwa yana da hankali, yana haifar da raguwa daban-daban na raguwa da nakasar jirgin yayin aikin sanyaya;

4. Saboda babban bambanci a cikin kauri, bambanci tsakanin ɓangaren kauri mai kauri ko ƙungiyar yankin canji da sauran sassan ƙungiyar yana ƙaruwa.

Hanyar rigakafi

1. Inganta matakin ƙirar ƙira, ƙira da gyaran ƙira;

2. Tabbatar da saurin sanyaya uniform.

XX.Tsarin girgiza

Wannan lahani ne na lokaci-lokaci yana juyewa zuwa saman samfurin da aka fitar.An kwatanta shi da ratsi na lokaci-lokaci a kwance a saman samfurin, kuma ɗigon ɗigon ya yi daidai da siffar bel ɗin aiki na mold, kuma a cikin lokuta masu tsanani, akwai wani abu mai ban sha'awa.

Babban dalilin girgiza

1. Ƙaƙƙarfan ƙaƙƙarfan motsi yana motsawa gaba kuma yana girgiza saboda dalilai na kayan aiki, wanda ke sa karfe ya girgiza lokacin da ya fita daga cikin rami;

2. Ƙarfe yana girgiza lokacin da ya fita daga cikin ramin mutuwa saboda ƙura;

3. Kushin goyon bayan mold bai dace ba, rashin ƙarfi na mold ba shi da kyau, kuma girgiza yana faruwa lokacin da ƙarfin extrusion ya canza.

Hanyar rigakafi

1. Yi amfani da ƙwararrun ƙira;

2. Ya kamata a yi amfani da madaidaicin tallafi na tallafi lokacin da aka shigar da ƙirar;

3. Daidaita kayan aiki.

XXI, Mixed

Babban dalilin haɗawa

Tunda billet ɗin haɗawa yana da ƙarfe ko waɗanda ba ƙarfe ba, ba a samo shi a cikin tsarin da ya gabata ba, kuma ya kasance a saman ko cikin samfurin bayan fitar da shi.

Hanyar rigakafi

Ƙarfafa binciken billet (ciki har da duban ultrasonic) don hana billet ɗin da ke ɗauke da ƙarfe ko abubuwan da ba na ƙarfe ba daga shiga tsarin extrusion.

XXII, Alamar Ruwa

Alamun fari mai haske ko haske baƙar fata mara daidaituwa na ruwa akan saman samfurin ana kiran su alamun ruwa.

Babban dalilin alamar ruwa

1. bushewa ba shi da kyau bayan tsaftacewa, kuma akwai ragowar danshi a saman samfurin;

2. Ragowar danshi a saman samfurin da ruwan sama ya haifar da wasu dalilai ba a tsaftace su cikin lokaci ba;

3. Man fetur na tanderun tsufa ya ƙunshi ruwa, kuma ruwa yana raguwa a saman samfurin a lokacin sanyi na samfurin bayan tsufa;

4. Man fetur na tanderun tsufa ba shi da tsabta, kuma saman samfurin ya lalace ta hanyar sulfur dioxide bayan konewa ko gurɓata da ƙura;

5. Matsakaicin kashe wuta ya gurɓace.

Hanyar rigakafi

1. Rike saman samfurin bushe da tsabta;

2. Sarrafa abun ciki na danshi da tsabta na cajin tsufa;

3. Ƙarfafa tsarin gudanarwa na quenching matsakaici.

XXIII.Tazarar

An sanya mai mulki a kwance a kan wani jirgin sama na samfurin extruded, kuma akwai wani rata tsakanin mai mulki da saman, wanda ake kira rata.

Babban dalilin tazarar

Ƙarfe mara daidaituwa a lokacin extrusion ko kammalawa mara kyau da ayyukan daidaitawa.

Hanyar rigakafi

Ƙirƙirar ƙira da ƙira a hankali, ƙarfafa gyaran gyare-gyare, da sarrafa zafin jiki da saurin extrusion daidai da ƙa'idodi.

XXIV, Kaurin bango mara daidaituwa

Kayayyakin da aka fitar masu girmansu iri ɗaya suna da katanga sirara ko kauri a cikin sashe ɗaya ko kuma madaidaiciyar hanya, kuma al'amarin ana kiran kaurin bango mara daidaituwa.

Babban dalilin rashin daidaito kaurin bango

1. Tsarin ƙirar ƙira ba shi da ma'ana, ko kayan aiki da taro ba daidai ba ne;

2. Silinda extrusion da allurar extrusion ba a kan layi ɗaya ba ne, suna samar da eccentricity;

3. Rufin silinda na extrusion yana sawa da yawa, kuma ba za'a iya daidaitawa da mold ba, yana haifar da eccentricity;

4. Ba za a iya kawar da kaurin bango mara daidaituwa na ingot blank kanta ba bayan extrusions na farko da na biyu.Ba a cire kaurin bango mara daidaituwa na ulu bayan extrusion ba bayan mirgina da mikewa;

5. Ana shafa man mai da ba daidai ba, wanda ke sa ƙarfe ya yi tafiya ba daidai ba.

Hanyar rigakafi

1. Inganta ƙira da ƙera kayan aiki da ƙira, da haɗawa da daidaitawa da hankali;

2. Daidaita tsakiya na extruder da extrusion mutu;

3. Zaɓi guraben da suka cancanta;

4. Madaidaicin iko na zafin jiki na extrusion, saurin extrusion da sauran sigogin tsari.

XXV.Fadada (da) baki

Lalacewar da ɓangarorin biyu na samfuran bayanan da aka fitar kamar tsagi da I-dimbin yawa ke karkata zuwa waje ana kiranta flaring, kuma lahanin da ke karkata a ciki ana kiransa layi ɗaya.

Babban abubuwan da ke haifar da haɓakawa (ƙarfafawa)

1. Yawan kwararar ƙarfe na "ƙafafu" biyu (ko "ƙafa ɗaya") na trough ko makamancin bayanin martaba ko bayanan martaba na I-dimbin yawa ba daidai ba ne;

2. A kwarara kudi na aiki bel a bangarorin biyu na tsagi kasa farantin ne m;

3. Na'ura mai daidaitawa mara kyau;

4. Bayan samfurin ya fita daga cikin mold rami, da online bayani jiyya ne m sanyaya.

Hanyar rigakafi

1. Tsananin sarrafa saurin extrusion da zafin jiki na extrusion;

2. Tabbatar da daidaito na sanyaya;

3. Daidaita ƙira da ƙira ƙira;

4. Tsananta sarrafa zafin jiki na extrusion da sauri, kuma shigar da kayan aiki kuma mutu daidai.

XXVI.Madaidaicin alamomi

Gilashin da aka yi a lokacin da aka miƙe naɗaɗɗen nadi na sama na samfurin da aka fitar ana kiran su alamar daidaitawa, kuma ba za a iya guje wa madaidaicin madaidaicin ba ga kowane samfurin da aka daidaita ta na sama.

Babban dalilin daidaita alamun

1. Akwai gefuna akan saman abin nadi na madaidaiciyar abin nadi;

2. Lankwasawa samfurin ya yi yawa;

3. Matsi mai yawa;

4. Kwancen nadi mai daidaitawa ya yi girma da yawa

5. Samfurin yana da babban ovality.

Hanyar rigakafi

Ɗauki matakan da suka dace don daidaitawa bisa ga dalilin.

XXVII.Alamun tsayawa, abubuwan gani nan take, alamun cizo

Dakatar da extrusion a lokacin extrusion don samar da ratsi a saman samfurin kuma daidai da hanyar extrusion, wanda ake kira alamomin tsayawa;layi ko ratsi a saman samfurin kuma daidai gwargwado ga hanyar extrusion yayin extrusion , wanda aka sani da alamun cizo ko abubuwan gani nan take (wanda akafi sani da "alamomin fakin ajiye motoci na karya")

A lokacin extrusion, abubuwan haɗin da aka manne a saman bel ɗin aiki ana ware su nan take kuma suna manne da saman samfurin da aka fitar don samar da alamu.Ratsin kwance na bel ɗin aiki wanda ke bayyana lokacin da aka dakatar da extrusion ana kiran su alamun filin ajiye motoci;Ana kiran ratsin da ke fitowa a lokacin aikin extrusion na gaggawa ko alamar cizo, kuma za su yi sauti yayin extrusion.

Babban abubuwan da ke haifar da alamun tsayawa, alamun nan take, da alamun cizo

1. Rashin daidaituwar zafin jiki na ingot ko canji kwatsam a cikin saurin extrusion da matsa lamba;

2. Babban sassa na mold ba su da kyau sosai da kuma ƙera su, ko taron bai dace ba kuma akwai gibi;

3. Akwai karfi na waje wanda yake daidai da hanyar extrusion;

4. Mai extruder ba ya gudu sosai, kuma akwai al'amari na rarrafe.

Hanyar rigakafi

1. Babban zafin jiki, jinkirin saurin gudu da kuma extrusion uniform, ƙarfin extrusion ya kasance barga;

2. Hana ƙarfin waje a cikin jagorar extrusion na tsaye daga aiki akan samfurin;

3. Madaidaicin ƙira na kayan aiki da ƙira, daidaitaccen zaɓi na kayan ƙirar ƙira, daidaita girman girman, ƙarfi da taurin.

XXVIII.Scratches a saman ciki

Ƙunƙarar da ke kan saman ciki na samfurin da aka fitar a lokacin aikin extrusion ana kiransa daɗaɗɗen saman ciki.

Babban abin da ke haifar da abrasion na ciki

1. An makale allurar extrusion tare da karfe;

2. Yanayin zafin jiki na allurar extrusion yana da ƙasa;

3. Matsayin da ke cikin allurar extrusion ba shi da kyau kuma akwai kullun;

4. The extrusion zafin jiki da kuma gudun ba a sarrafa sosai;

5. Rashin daidaitaccen rabo na mai mai extrusion;

Hanyar rigakafi

1. Ƙara yawan zafin jiki na silinda extrusion da allurar extrusion, da kuma sarrafa zafin jiki na extrusion da saurin extrusion;

2. Ƙarfafa tace man mai, bincika ko maye gurbin man da ba ta dace ba akai-akai, sannan a shafa mai daidai da dacewa;

3. Tsaftace saman ulu;

4. Sauya gyare-gyare marasa cancanta da alluran extrusion a cikin lokaci, kuma kiyaye saman gyare-gyaren extrusion mai tsabta da santsi.

XXX.Wasu dalilai

A cikin wata kalma, bayan m jiyya, 30 irin lahani na sama da aka ambata aluminum gami extrusion kayayyakin za a iya yadda ya kamata shafe, high quality, high yawan amfanin ƙasa, tsawon rai, da kuma kyakkyawan samfurin surface, samar da wani iri, kawo vitality da wadata zuwa ga kasuwanci, da kuma samun gagarumin fa'idodin fasaha da tattalin arziki.

XXX.Wasu dalilai

A cikin wata kalma, bayan m jiyya, 30 irin lahani na sama da aka ambata aluminum gami extrusion kayayyakin za a iya yadda ya kamata shafe, high quality, high yawan amfanin ƙasa, tsawon rai, da kuma kyakkyawan samfurin surface, samar da wani iri, kawo vitality da wadata zuwa ga kasuwanci, da kuma samun gagarumin fa'idodin fasaha da tattalin arziki.

Lokacin aikawa: Agusta-14-2022