sandar extrusion ko rago extrusion a cikin injin latsawa na aluminum extrusion

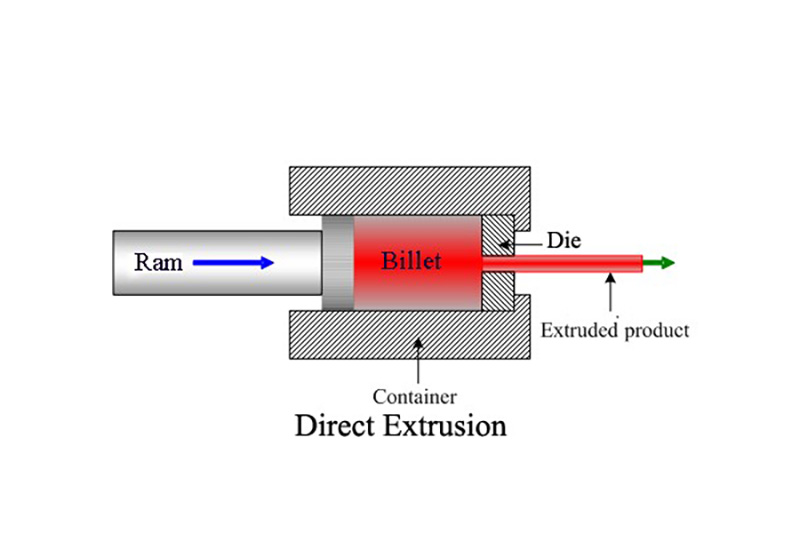

Ragon extrusion ya kasu kashi biyu: m da m.Ana amfani da raguna masu ɓarna a cikin bututu da injunan extrusion na sanda.

Ragon extrusion gabaɗaya tsarin silindrical ne, wanda za'a iya raba shi zuwa iyakar, sanduna da tushensu.

A kan manyan masu fitar da ton, an yi raguna na extrusion da sassa daban-daban don ƙara ƙarfin lanƙwasawa mai tsayi.A wannan lokacin, silinda extrusion ya kamata ya sami rami na ciki tare da sashin giciye mai canzawa.

Ana ƙayyade diamita na waje na ragon extrusion bisa ga diamita na ciki na silinda extrusion.

Diamita na waje na ragon extrusion na kwance a kwance ya fi girma fiye da na ragon extrusion.Diamita na ciki na Silinda shine ƙarami 4-10mm.

Tsawon rago na extrusion daidai yake da tsayin mai goyon bayan ragon extrusion tare da tsawon silinda na extrusion da 5 zuwa 10mm, don tura yawan matsa lamba (duba sauran kayan extrusion) da gas din extrusion daga cikin silinda extrusion.Kayan rago na extrusion shine chrome-nickel-molybdenum da chrome-nickel-tungsten gami.Jikin sandar da aka haɗe an yi shi ne da chromium-nickel-tungsten-vanadium gami, kuma tushen an yi shi da chromium-nickel-molybdenum gami.

Ragon extrusion yana fuskantar babban damuwa na lankwasawa na tsayi da damuwa yayin aiki.Saboda haka, da kwanciyar hankali da kuma

Ya kamata a duba ƙarfin ragon extrusion yayin extrusion.